Cameron自动化 架 & 堆栈

的 架 & 堆栈 is the second generation of Cameron Automation’s Flooring Nesters. Designed to nest flooring strips up to 5″ wide and bundles up to 7.5英尺长,架子 & 堆栈的生产力提高了20%, 占了1/2的空间, and requires less operator intervention than our previous designs.

机器是做什么的?

卡梅伦货架 & 堆栈 creates accurate nested flooring bundles. Graders feed random lengths of material into one end of the machine, and the 架 & 堆栈 releases a consistent, nested bundle of flooring out the opposite end. 最重要的是, it creates bundles the exact square footage you want to sell, 增加你的利润最多2.5%. A 2.5% yield savings equates to one extra bundle for every 40 you ship!

这个软件是做什么的?

Cameron software is written and supported at our factory in Poughkeepsie, NY. This enables us to provide our customers with updates, 变化, 而且升级速度快,而且经常免费. In house programmers allow us to react to our customer’s needs rapidly. 的 software is intuitive, easy to understand.

Cameron自动化 架 & 栈软件:

- Designs bundles that meet the needs of your customers.

- Measures each and every board so you have all incoming and outgoing data.

- Controls shorts in each bundle by changing software parameters.

- 打印包标签(可选).

- 生成的报告包括:

- 包了

- 平方英尺

- 加工过的板材及更多

它是如何工作的

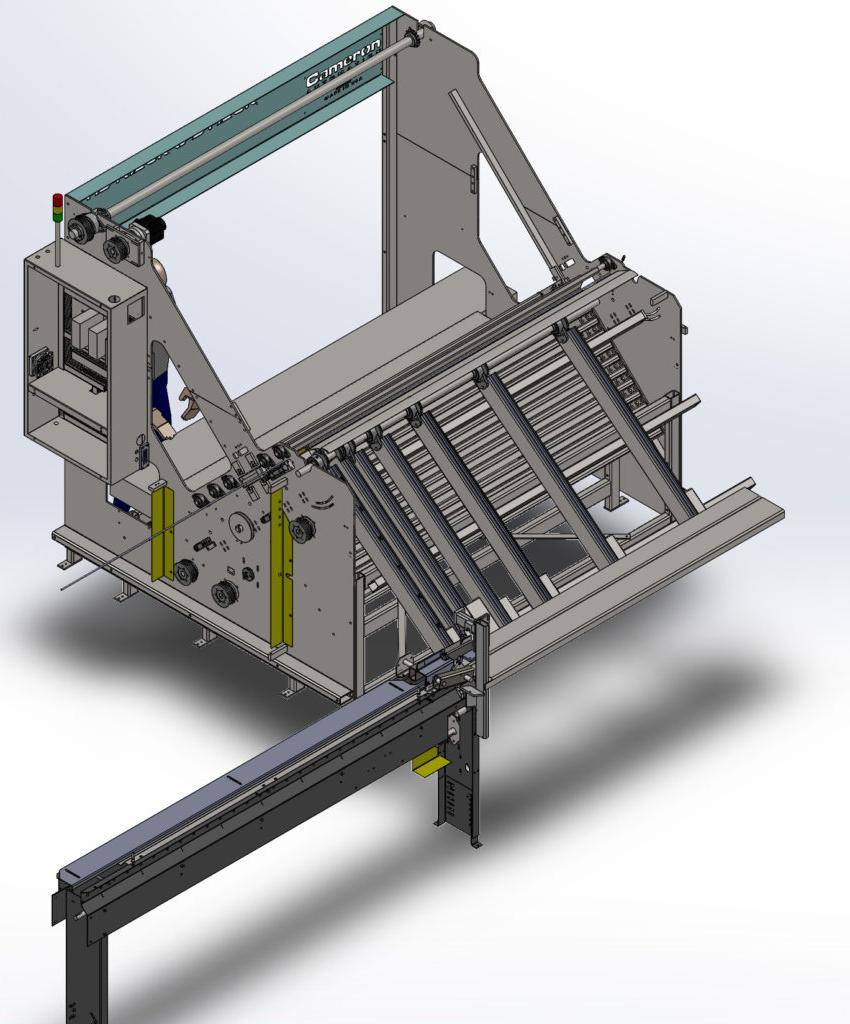

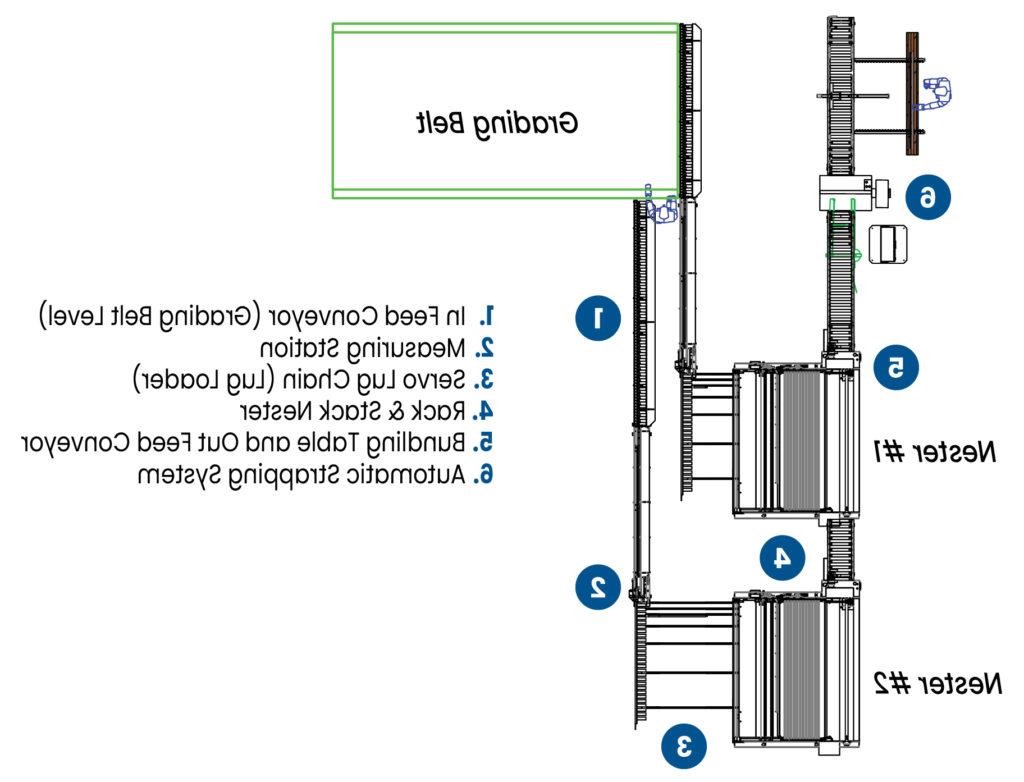

- 进料输送机(分级带级) Flooring strips of random length are fed from the grading belt onto the in feed conveyor and delivered to the measuring station. 的 measuring station singulates flooring strips, measures the length and delivers them to the lug chain. 的 servo lug chain (inclined) lifts flooring strips from the measuring station to the first and second stops at the beginning of the sorting section.

- 架 & 堆巢(分拣站) 的 rack (with slots) moves up and down continuously delivering the proper strips to build a bundle. When the rack stops, a flooring strip drops out and new flooring strip drops in. With 12 available slots the number of combinations to build accurate lengths and accurate bundles is in the thousands, 因此收益更高!

- 捆扎台及出料输送机 的 bundling table is in almost continuous motion gathering and aligning rows and layers of flooring. 当一个包完成时, it is pushed onto the out feed conveyor and delivered to the strapping system.

- 自动捆扎系统 的 automatic strapping system can be programmed for different strap spacing and different bundle lengths. Strapped bundles are then delivered to the out feed rack for temporary storage.

Information on the Out-feed Systems for the Nester can be found below

今天浩博体育app,了解更多关于机架 & 堆栈以及它如何使您的业务受益!