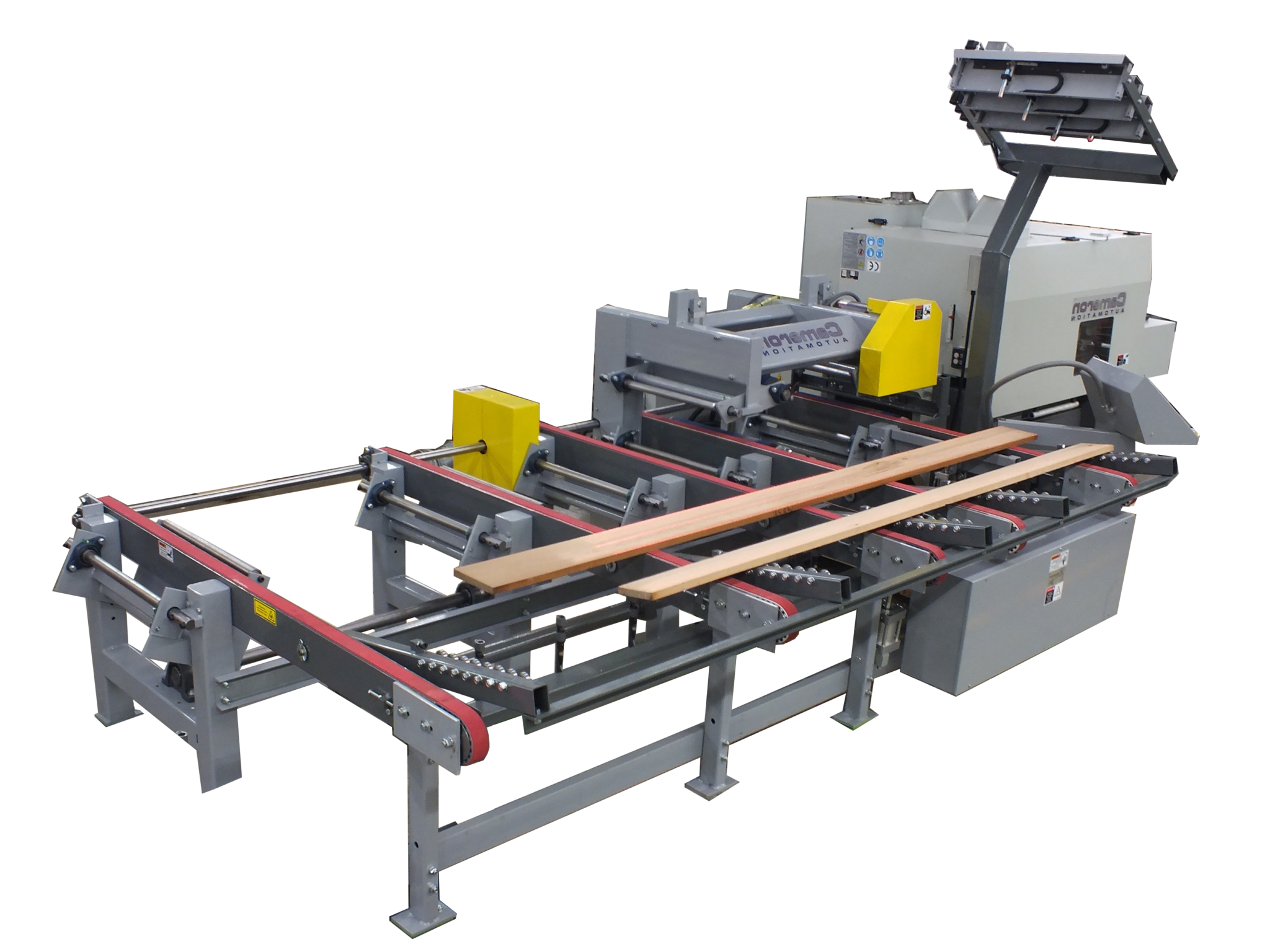

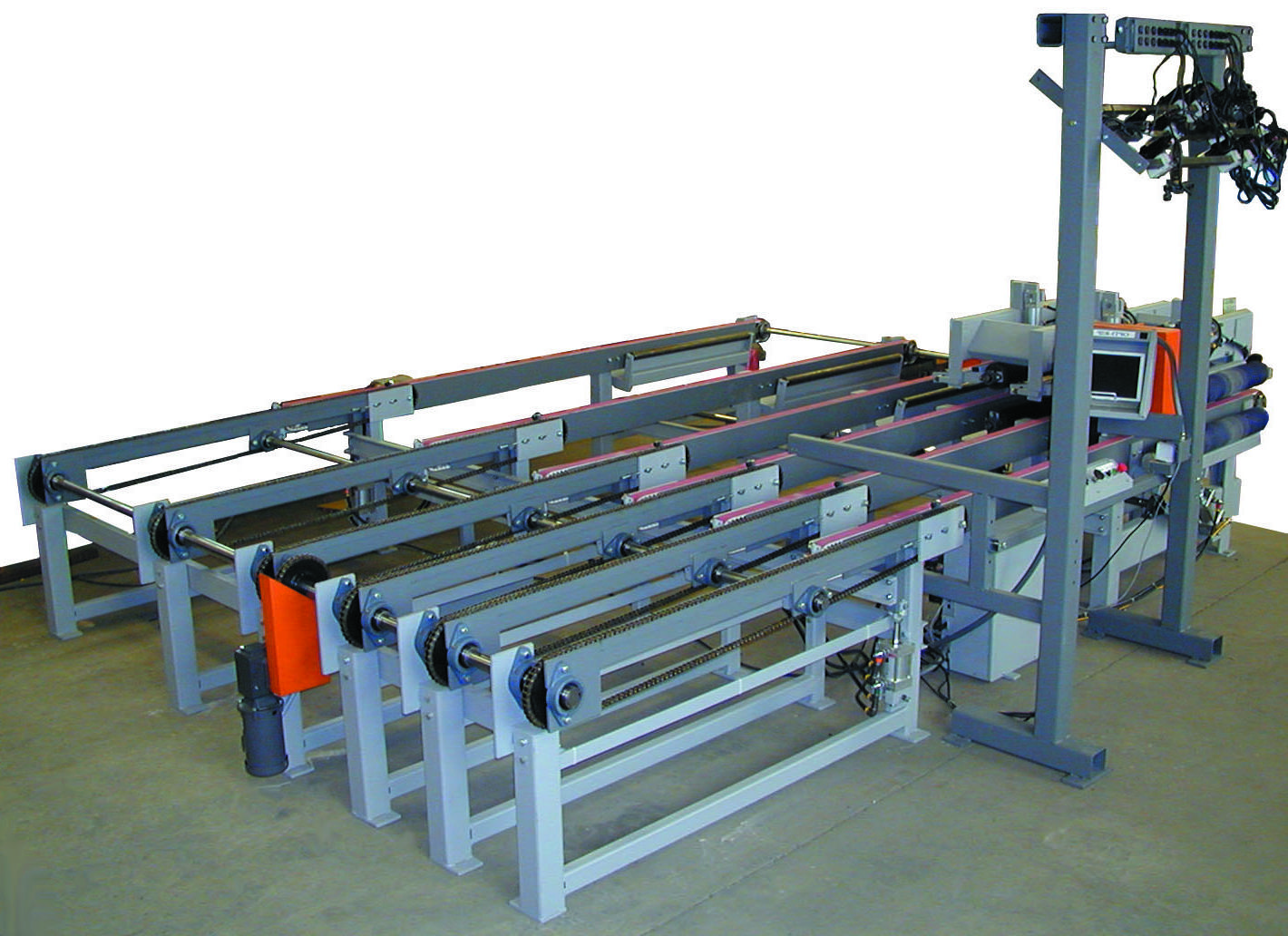

The Skew is a highly efficient, 便宜的, 全功能的, rip optimization system designed to fit any 12″ wide gang rip saw and specifically developed for the custom shop. The unique feature of The Skew is the “skewing fence”. It has the ability to twist and feed the board into the saw to get the best yield. The Skew also has all the features of the high-end optimization systems like: lumber tallying, 包报告, 束报告, 收益率的计算, 模拟, 还有更多. The greatest benefit of The Skew is the Return on Investment, which can be well under 1 year.

Typical Skew Rip System Customers:

- 成型 & 木工店

- 内阁的商店

- 地板制造商

- Wholesale Lumber Distributor

- 门生产厂家

- 楼梯 & 栏杆制造商

Many Skew Systems include a Cameron (2) or (3) Moving Blade Rip Saw, but with our Cameron Opti-Rip Software, we are able to communicate with Moving Blade Saws from other Manufacturers: Mereen-Johnson, Raiman, Cantek, and Kentwood to name a few.